XL3

Key XL3 Features

(500 x 500 px).png?)

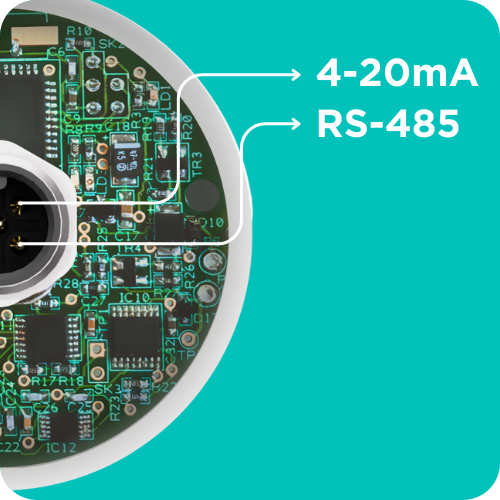

Analogue and

Digital Outputs

✓ Line viscosity

✓ Temperature corrected viscosity

✓ Line temperature

A single 4-20mA output to simplify functionality. Representing either viscosity, referenced viscosity or temperature. And an RS-485 digital output means all measured data values are available if required.

Standalone

It’s all in the head

XL3 utilises Hydramotion’s integrated smart head electronics. That means direct analog and digital signals are transmitted with super-high integrity over unlimited cable lengths.

And the simple connector eliminates cumbersome wiring which means faster deployment with no additional equipment.

Discover XL3

InstallationLearn more > |

SpecificationsLearn more > |

DownloadsLearn more > |

Install in minutes. Monitor instantly.

Forget complex installations. The XL3 drops straight into small-bore pipes or tanks and gets to work instantly. No moving parts, no fragile components, and no tedious calibration routines.

This is plug-and-play viscosity measurement, with the stability and speed you’d expect from Hydramotion.

XL3 Connectivity Options

StandaloneGet fast reliable data directly from the instrument. Perfect for simple installations and connecting with existing DCS systems. Our smart head electronics handle everything from signal conditioning to output processing. All from standard cables over any distance. |

ProcessorWhere a local display is preferred, the VP250 Processor provides all the functions needed to get more out of your mini viscometer. Critical viscosity data and sensor management are available at the touch of a button including multidrop configuration for multiple units. |

Designed and Built

at the HTC

All viscometers are designed and manufactured at the Hydramotion Technology Centre, UK.

State-of-the-art machining, welding and production facilities means Hydramotion maintains complete end-to-end control over quality and performance across the entire product range.

Hydramotion’s Quality and Validation Labs verify every instrument against traceable international standards – the benchmark behind the Hydramotion seal of approval.

3 Daily Profit Drivers

Increase QualityAchieve end-product quality by tracking process change in real-time and proactively take action. |

Eliminate WasteInstantly detect off-spec product or process drift and adjust the process in real-time to bring the material back into spec. |

Transform ProductivityAutomate your viscosity measurement and control and reduce reliance on manual offline measurements. |

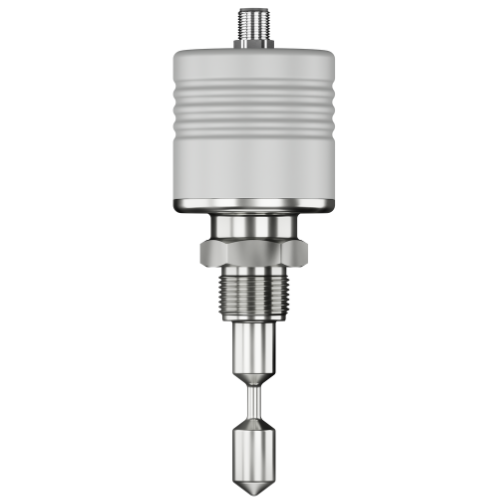

The mini inline viscometer

with the Hydramotion seal of approval

XL3 delivers real-time, high-stability viscosity measurement in a compact, standardised form. Standalone operation means no need for a digital processor, so signals can output straight into a DCS system with no intermediary.

Immune to mounting orientation XL3 features a standard threaded fitting for straightforward installation and consistent process integration. Once installed, it requires no calibration, no maintenance, and no reconfiguration, making it as scalable as it is precise. Hydramotion performance, made accessible.

Designed to make a difference.

Speed, stability and sensitivity are all signature features of a Hydramotion viscometer. And all features you need to run a repeatable process.

The XL3 is a mini viscometer designed to give you a simple and reliable viscosity signal to keep your process running smoothly and your product in spec. All with a small form factor for direct installation in small bore pipes and tanks.

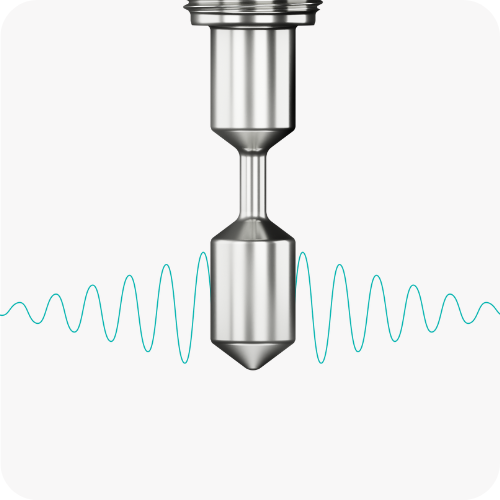

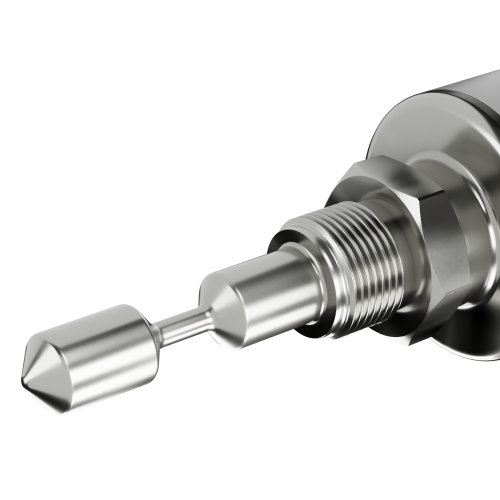

With trusted resonant technology.

The XL3 utilises the proprietary Hydramotion torsional resonant technology, meaning the XL3 is simultaneously sturdy and fluid-sensitive.

Calibration is maintained regardless of installation, flow, bubbles or solids. Which means there are no on-site ‘adjustments’. So you can locate, or relocate your viscometer anywhere

Where Sensitivity.

Meets Stability.

The XL3 is amazingly sensitive – able to detect subtle changes in viscosity, even down to a glass of water as it warms up to room temperature.

And that sensitivity is maintained even at process conditions, backed by the XL3’s inherent signal stability and resistance to process noise.

Software Options

VLink

Configuration Utility

A simple configuration utility to get XL3 up and running quickly.

Access basic parameters and scaling factors at the click of a button. Included as standard for standalone mode.

ViscoLink 4

Data Logger

ViscoLink provides a more advanced, Windows-based platform for capturing, calculating, and logging measurement data on any PC, laptop, or tablet.

*Available separately

.png?)

Ready to learn more?

Contact Hydramotion to learn more about XL3 or discuss your requirements.